Have a specific design in mind but can't find it in standard quartz collections? This forces you to compromise, leaving your project feeling generic and not quite "you."

Manufacturers offer customizable quartz to meet unique aesthetic tastes, specific project dimensions, and the growing demand for personalized designs. This allows clients to create spaces that perfectly match their vision, from custom colors and patterns to precise functional fits.

For years, I've seen the look of relief on a client's face when they realize they don't have to settle for "close enough." Customization is where a manufacturer stops being just a supplier and becomes a creative partner. It's about transforming a functional surface into a personal statement. Let's explore why this has become such a crucial part of the quartz industry.

Is there a difference between quartz manufacturers?

Assuming all quartz suppliers are the same? This thinking can lead to big disappointments when you discover huge gaps in quality, service, and the ability to deliver on your vision.

Yes, there are major differences. Manufacturers vary greatly in their quality control, technological capabilities, and willingness to offer customization. The best partners invest in technology and processes that allow them to create truly tailored solutions for their clients.

The ability to customize is a key factor that separates average suppliers from great partners. It shows a commitment to meeting client needs rather than just moving inventory. A few years ago, a contractor from Australia contacted us. He was frustrated with his current supplier's "what you see is what you get" attitude. He had a specific, intricate pattern in mind for a luxury development. We worked closely with him, using our digital printing technology to embed the unique design directly into the quartz slab. He was blown away by the result and has been a loyal partner ever since. This level of service is our competitive edge. It turns a simple transaction into a lasting relationship built on trust and innovation.

Standard vs. Custom-Focused Manufacturers

Understanding the difference helps you choose the right partner for your project's needs.

| Feature | Standard Manufacturer | Custom-Focused Manufacturer |

|---|---|---|

| Product Offering | Limited, mass-produced catalog | Wide range plus bespoke options |

| Technology | Basic production machinery | Advanced tech like digital printing & CNC |

| Client Relationship | Transactional | Collaborative partnership |

| Flexibility | Rigid; limited to stock items | Adaptable; creates new solutions |

What is the difference between quartz and manufactured quartz?

Hearing terms like "quartz," "engineered quartz," and "manufactured quartz" is confusing. You're not sure if they mean different things, which creates uncertainty when you're trying to buy.

There is no difference in the context of countertops. "Quartz" is the common term for "manufactured" or "engineered" quartz. It's a composite material made from natural quartz crystals (about 90%), resins, and pigments, which are engineered for durability and design flexibility.

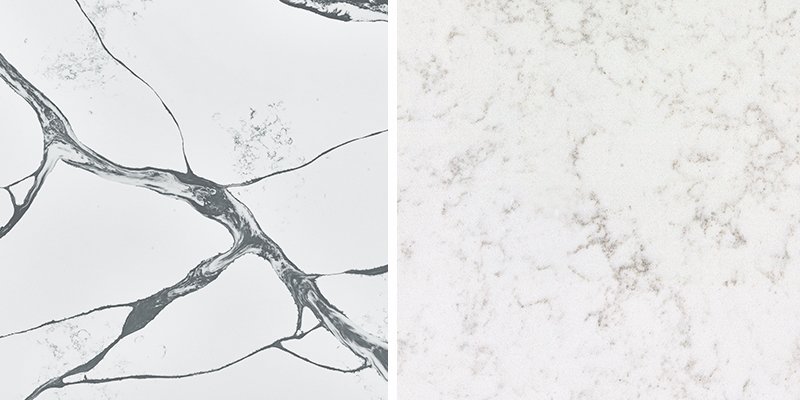

The fact that quartz countertops are manufactured is their greatest strength. It’s this engineering process that allows for customization. We aren't just quarrying a slab from the earth; we are creating it. In my factory, we start with pure, ground natural quartz. We then blend it with high-quality resins and carefully selected pigments. This is where the magic happens. A client in Europe might want the classic look of Calacatta marble without the maintenance. By adjusting the pigments and the way we create the veining during production, we can replicate that natural beauty in a more durable material. This process gives us complete control over the final product, from color and pattern to its physical properties, turning a client's vision into a reality.

The Composition of a Quartz Slab

Understanding the components shows why engineered quartz is both durable and endlessly customizable.

| Component | Percentage | Role in the Slab |

|---|---|---|

| Natural Quartz Crystals | ~90-93% | Provides hardness, durability, and scratch resistance. |

| Polymer Resins | ~7-10% | Binds the quartz crystals together, making the slab non-porous. |

| Pigments | <1% | Creates the color, patterns, and veining. This is key for customization. |

| Additives | <1% | Can include recycled glass or metallic flecks for unique aesthetic effects. |

What are the different quartz options?

You want to choose quartz, but the number of options feels endless. You don't know what's possible or how to ask for what you really want, making the selection process stressful.

Quartz options go far beyond color. They include custom veining, specific slab dimensions, unique edge profiles, different finishes like polished or matte, and precise cutouts for sinks and fixtures. Essentially, almost any element can be tailored to your project.

Customization allows us to serve an incredibly wide range of needs. It's about adapting to function, style, and even cultural tastes. For instance, I've noticed that our clients in Southeast Asia often prefer bold, vibrant colors, while our partners in North America tend to lean towards neutral tones with complex, organic veining. We adjust our production to meet these regional trends. On the functional side, I recall a project for a U.S. client who needed countertops for an unusually shaped kitchen island. We used our computerized cutting machines to create slabs with precise angles and dimensions. We also crafted a specific bullnose edge profile they requested. This level of detail ensures the final product fits perfectly and looks completely integrated into the space.

Common Customization Requests

Here are some of the most popular ways we tailor quartz for our clients.

| Option | Description | Best For |

|---|---|---|

| Color Matching | Creating a unique slab color based on a sample (e.g., a paint chip). | Achieving a perfect match with cabinets, flooring, or brand colors. |

| Vein Customization | Adjusting the thickness, color, and flow of veins to be subtle or bold. | Mimicking specific types of natural stone or creating a one-of-a-kind design. |

| Custom Sizing | Producing slabs in non-standard dimensions, including jumbo sizes. | Large kitchen islands, seamless backsplashes, and minimizing waste. |

| Edge Profiles | Cutting and polishing edges into specific designs (e.g., ogee, bullnose). | Matching a specific design style, from traditional to modern. |

Why are some quartz countertops more expensive than others?

You're seeing a wide variety of prices for quartz and can't figure out why. This makes it difficult to budget properly or know if you're getting a fair price for the quality.

Prices vary based on the complexity of the design and the quality of the materials. Highly customized countertops with intricate patterns, unique colors, or jumbo dimensions require more advanced technology, skilled labor, and premium raw materials, making them more expensive than standard options.

Simply put, complexity adds cost. A standard, mass-produced white quartz slab is efficient to make. However, a custom project requires a lot more. I remember working with a hotel chain in Dubai that wanted a consistent but unique pattern across hundreds of bathroom vanities. We developed a proprietary design for them, which involved creating a new pigment formula and programming a specific veining pattern. This development process, combined with the need for absolute consistency from slab to slab, adds to the final cost. It's not just about the raw materials; it's about the research, technology, and meticulous craftsmanship required to create something that doesn't exist yet. The higher price reflects the added value of a truly bespoke product.

Key Factors Influencing Quartz Price

The final cost is a reflection of the resources needed to produce the slab.

| Cost Factor | Why it Increases Price |

|---|---|

| Pattern Complexity | Intricate, multi-layered veining requires more advanced machinery and artistry than simple patterns. |

| Custom Color | Developing a new color formula involves R&D, test batches, and premium pigments. |

| Slab Size | Jumbo slabs require larger molds, presses, and specialized handling equipment. |

| Brand & Quality | Reputable brands invest more in high-purity quartz, superior resins, and strict quality control. |

Conclusion

Customization is a manufacturer's promise to bring your vision to life. It transforms quartz from a simple commodity into a personalized solution, ensuring your project is truly one-of-a-kind.