Are you struggling to choose between modified and 100% acrylic solid surfaces? Making the wrong choice can impact your project's budget and quality, causing headaches you don't need.

The main difference is the resin used in their composition. 100% acrylic solid surface uses pure acrylic resin, giving it superior flexibility for bending and better durability. Modified acrylic solid surface uses a blend of polyester and acrylic resins, which makes it cheaper but less performant.

Understanding this core difference is the first step. But as a procurement manager, you need to know how these differences play out in real-world applications, from fabrication to final installation. In my 13 years in this industry, I've seen how picking the right material from the start saves time, money, and protects your reputation. Let's break down what these distinctions mean for your projects so you can source with complete confidence.

What is the difference between solid surface and acrylic?

Is "solid surface" just another name for "acrylic"? This common confusion can lead to specifying a material that doesn't meet your project's demands. Let's clear this up right now.

"Solid surface" is the general material category. "Acrylic solid surface" is a premium type within that category, defined by its use of 100% pure acrylic resin. This resin difference is what separates standard performance from the high-end durability and flexibility your clients expect.

In my line of work, I talk to procurement managers like you every day. The term "solid surface" generically describes a man-made composite material. At their core, all solid surfaces are made of a mineral filler, which is almost always aluminum trihydrate (ATH), and a resin binder that holds it all together. The real story, and the source of all the performance differences, is in that resin. You have different types, and this is what you must pay attention to. Think of it as the key ingredient that defines the final product's character and capabilities. For anyone sourcing materials, knowing the resin type is non-negotiable.

Resin: The Deciding Factor

The type of resin binder used changes everything from fabrication possibilities to long-term durability. It's the single most important factor to consider when you write a specification.

| Feature | 100% Acrylic Solid Surface | Modified Solid Surface |

|---|---|---|

| Resin Type | 100% Acrylic Resin (MMA + PMMA) | Polyester Resin + Acrylic bits (MMA) |

| Performance | High (Durable, Thermoformable) | Standard (Less flexible, more brittle) |

| Best For | High-end projects, curved designs | Cost-sensitive projects, flat surfaces |

What does "modified acrylic" mean?

Have you seen the term "modified acrylic" on a spec sheet and wondered what was changed? Using it without knowing could risk the integrity of your final installation. Let's define it.

"Modified acrylic" means the binder is primarily a polyester resin that has been "modified" with a small amount of acrylic resin (MMA). This formulation lowers the manufacturing cost but also reduces durability, stain resistance, and especially its ability to be bent with heat.

The term "modified" sounds technical, but it’s really about cost engineering. The primary resin is a less expensive unsaturated polyester resin (UPR). To improve its properties slightly and to use the "acrylic" label, manufacturers add a small percentage of methyl methacrylate (MMA), often around 10-12%. In contrast, what we call 100% or pure acrylic solid surface uses only pure acrylic resin, which is a mix of MMA and PMMA. This pure acrylic binder is what provides superior performance. From my position in China, I see how raw material costs and export policies influence these formulations. Modified acrylic serves the need for a lower-cost material, especially in domestic or price-driven markets, while 100% acrylic is produced for global clients who demand top-tier quality and design freedom.

Performance Trade-offs

Choosing modified acrylic is a cost-saving measure, but it comes with significant trade-offs in performance that you must account for in your project planning.

| Property | 100% Acrylic | Modified Acrylic |

|---|---|---|

| Composition | ~38% Pure Acrylic Resin | ~38% Polyester Resin with MMA |

| Bending Ability | Excellent. Can be thermoformed into tight curves. | Poor. Minimal bending radius of R600mm. |

| Hardness (Barthel) | Higher, around 70. More durable. | Lower, around 58-60. Easier to scratch. |

| Cost | Higher initial investment. | Lower initial cost. |

What is acrylic solid surface used for?

You know 100% acrylic is a premium material, but do you know its full potential? You might be missing out on applications that could set your projects apart. Let's look at its uses.

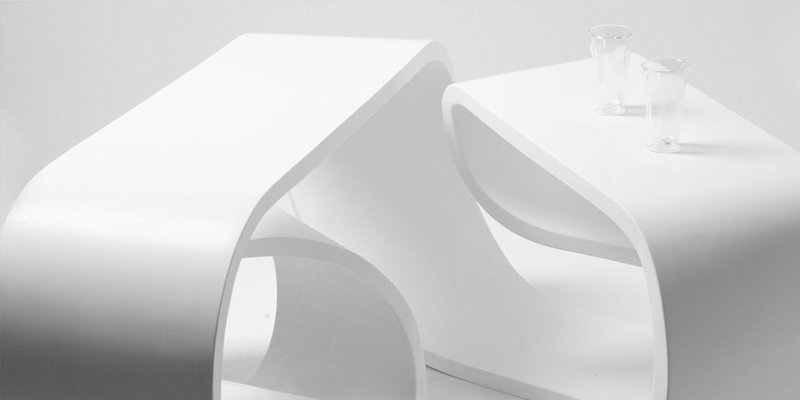

100% acrylic solid surface is used for seamless kitchen countertops, integrated sinks, hygienic wall cladding, and custom reception desks. Its greatest strength is thermoformability, allowing it to be bent into complex, curved shapes for designs that other materials simply cannot achieve.

The versatility of 100% acrylic solid surface comes from its unique combination of properties. Because it's non-porous, it’s completely hygienic and resists stains, making it a top choice for healthcare, laboratories, and food service environments. Its ability to be joined seamlessly means you can create long, continuous surfaces with no visible joints, which is perfect for large kitchen islands and countertops. But the real magic is in thermoforming. I once worked with a client designing a boutique hotel. They wanted a front desk that flowed like a ribbon. Modified acrylic was not an option; it would have cracked. With 100% acrylic, we heated the material and bent it into the exact fluid shape the architect envisioned. It became the centerpiece of their lobby.

Applications Driven by Performance

The best applications for 100% acrylic solid surface are those that leverage its key strengths: seamlessness, hygiene, and design flexibility.

| Application Area | Why 100% Acrylic is the Best Choice |

|---|---|

| Commercial Reception Desks | Thermoformable for unique, flowing shapes that make a strong brand statement. |

| Healthcare & Labs | Completely non-porous and seamless for a hygienic, easy-to-disinfect surface. |

| Residential Kitchens | Allows for integrated sinks with no gaps for dirt, creating a clean and modern look. |

| Retail & Hospitality | Can be used for creative displays, elegant bar tops, and durable wall features. |

What are the disadvantages of solid surface countertops?

Considering solid surface but worried about the potential downsides? Every material has weaknesses. Knowing them upfront prevents client disappointment and costly callbacks. Let's be honest about them.

The main disadvantages are lower heat resistance compared to natural stone and being softer, so it can scratch. You can't place hot pans directly on it. However, its biggest advantage is that damage like scratches can be easily sanded out and repaired on-site.

Transparency is key to trust, so I always discuss these points with my clients. Yes, solid surface is more sensitive to heat than granite. A hot pan set directly on the surface can cause discoloration or damage. This is easily prevented by using trivets. It is also softer than quartz or granite, so it will show scratches from knives or abrasive materials. This is why cutting boards are essential. But here is the critical balancing factor: solid surface is renewable. Unlike a chip in quartz or a crack in granite, which are difficult and expensive to fix, scratches and minor damage on a solid surface can be buffed out by a professional, leaving the countertop looking brand new. This repairability is a huge long-term value for any client.

Identifying and Managing Weaknesses

Knowing the weaknesses allows you to educate your clients and manage their expectations, ensuring long-term satisfaction. I even teach clients simple field tests to verify they received the 100% acrylic they paid for. When you burn a small sample, 100% acrylic gives off a sweet, fruity smell, while modified acrylic has a harsh, chemical odor. This quick check ensures quality control on site.

| Disadvantage | Mitigation Strategy | How it Compares to Other Materials |

|---|---|---|

| Heat Sensitivity | Always use trivets for hot pans. | More sensitive than granite, but less brittle and won't crack from thermal shock. |

| Scratch-Prone | Use cutting boards. Avoid abrasive cleaners. | Softer than quartz, but unlike quartz, scratches and marks can be fully repaired. |

| Chemical Sensitivity | Clean spills quickly. Avoid harsh solvents. | Excellent resistance to most household chemicals, but acetone should be avoided. |

Conclusion

In summary, choose 100% acrylic solid surface for performance, durability, and design freedom. Opt for modified acrylic for budget-driven projects with simple, flat surfaces. Always verify the material is right.